Washers

High-quality washers for secure & stable fixings

Washers are a crucial component in fastening systems, helping to distribute loads, reduce friction, and protect surfaces from damage. Used in construction, engineering, and industrial applications, washers provide stability, durability, and improved fastening efficiency.

Whether you're working with thermo washers for insulation, turned washers for high-precision fittings, or VGU washers for specialised applications, choosing the right washer ensures stronger, longer-lasting connections.

Our range of washers, including turned and thermo washers, ensures strong, even load distribution for secure fixings. Designed for durability and reliability, they help prevent damage and enhance fastening strength. Explore our washer range today.

-

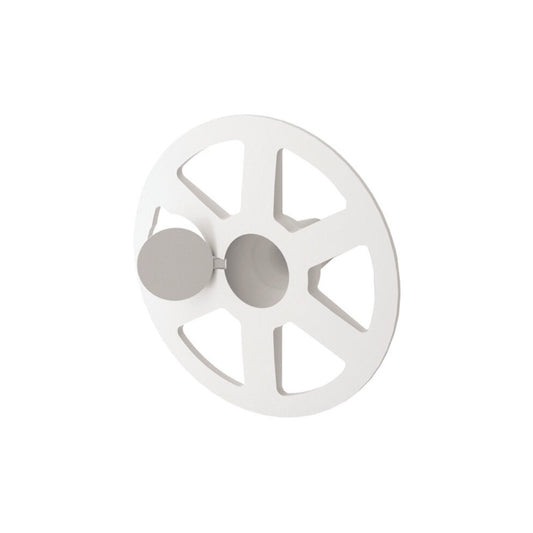

VGU - 45° washer for VGS

Regular price From £54.84 GBPRegular priceUnit price / per -

HUS Turned Washer (Box of 50)

Regular price £15.67 GBPRegular priceUnit price / per -

Thermo Washer (box of 700)

Regular price £207.43 GBPRegular priceUnit price / per -

MET Threaded Rods, Nuts and Washers

Regular price From £29.81 GBPRegular priceUnit price / per

Why are washers important?

Washers serve several key functions in fastening systems, ensuring that bolts, screws, and nuts hold securely without causing damage or loosening over time.

The primary purposes of washers include:

- Load distribution – spreads the force of a fastener over a larger area to prevent surface damage.

- Prevention of loosening – reduces the risk of fasteners becoming loose due to vibrations or movement.

- Surface protection – prevents scratches, cracks, or dents on the material being fastened.

- Improved clamping force – helps secure connections by preventing excessive stress on one point.

- Corrosion and heat resistance – some washers provide protection against environmental factors, including moisture, chemicals, and high temperatures.

What are the benefits of using washers?

Using washers in fastening systems offers several advantages:

- Enhanced fastening strength - Washers provide better stability and grip, ensuring that screws and bolts remain securely in place even under tension.

- Increased lifespan of materials - By reducing friction and preventing over-tightening, washers help protect surfaces from wear and deformation.

- Better resistance to vibrations - Washers, particularly locking and spring washers, help absorb vibrations, reducing the risk of fastener loosening in dynamic applications.

- Improved thermal and electrical insulation - Specialised washers, such as thermo washers, help prevent heat transfer between fasteners and the materials they secure.

- Versatility for different applications - Washers come in a variety of materials and designs, allowing them to be used in construction, automotive, aerospace, electrical systems, and machinery.

What are thermo washers used for?

Thermo washers are designed to provide thermal insulation between fasteners and surfaces, helping to prevent heat transfer and manage temperature fluctuations in assemblies.

Common applications of thermo washers

- Electrical installations – used to insulate metal fasteners in electrical systems, reducing the risk of electrical conduction.

- Heat-sensitive equipment – helps protect components in electronics, HVAC systems, and industrial machinery from excessive heat exposure.

- High-temperature environments – prevents heat transfer in boilers, heating systems, and engine components, protecting materials from thermal expansion and stress.

Made from heat-resistant materials such as ceramics, rubber, or composite plastics, thermo washers play a crucial role in maintaining safe and efficient mechanical operations.

What are turned washers used for?

Turned washers are precision-machined washers designed for applications requiring high accuracy, tight tolerances, and superior load distribution. Unlike stamped washers, turned washers are manufactured using CNC machining or lathes, ensuring smooth finishes and exact dimensions.

Common uses of turned washers

- High-precision engineering – used in aerospace, automotive, and industrial machinery where exact tolerances are required.

- Load bearing applications – provides extra strength and even force distribution in mechanical fastenings.

- Bespoke components – often custom-made for specialist applications requiring non-standard dimensions.

Turned washers are typically made from steel, stainless steel, brass, or aluminium, providing high durability and resistance to wear and tear.

What are VGU washers used for?

VGU washers are a specialised type of washer used in applications where vibration resistance, grounding, or unique sealing properties are required.

Common applications of VGU washers

- Vibration control – helps reduce mechanical vibrations in machinery, preventing fastener loosening over time.

- Grounding applications – in electrical assemblies, VGU washers can act as electrical conductors or insulators depending on the material used.

- Sealing and protection – some VGU washers are designed to provide a tight seal against moisture, dust, or contaminants, making them ideal for outdoor and industrial environments.

VGU washers are often made from specialised materials such as rubber-coated metal, composite alloys, or conductive metals to suit different industrial needs.

Washers are essential in fastening systems, providing better load distribution, protection against damage, and enhanced mechanical performance. Whether you need thermo washers for heat insulation, turned washers for precision engineering, or VGU washers for vibration control and grounding, selecting the right washer ensures secure and long-lasting connections.

By understanding how washers work, their benefits, and their applications, builders, engineers, and manufacturers can achieve stronger, more reliable, and safer fastening solutions for various industries.

Timber build advice:

-

How to soundproof a timber house?

Find out how -

How to connect timber to…..?

Find out how -

How to fix timber build noise issues?

Find out how

Need advice on your timber project?

Our team of experts are ready to assist you with any questions or guidance you may need for your timber construction. Whenever you're ready to delve deeper into the possibilities, feel free to reach out to us.