Angle Brackets

Heavy-duty metal brackets for reinforced structural support

Angle brackets are one of the most versatile and essential components in construction, woodworking, and engineering. Designed to provide strength and stability, these brackets reinforce joints, connections, and load-bearing structures, ensuring secure and long-lasting installations.

Whether you're using heavy-duty angle brackets for structural applications, 90-degree angle brackets for precise corner reinforcement, or metal angle brackets for general construction, selecting the right bracket is key to enhancing strength and load distribution in any project.

Perfect for reinforcing timber and metal structures, our angle brackets provide exceptional strength and stability. Whether for DIY or professional builds, they offer a secure and long-lasting connection. Browse our angle brackets now.

-

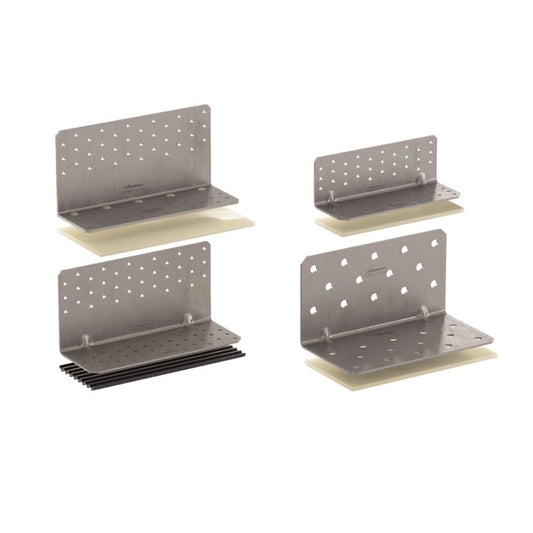

Titan Silent Angle Bracket

Regular price From £9.27 GBPRegular priceUnit price / per

What is an angle bracket?

An angle bracket is a metal or plastic L-shaped support designed to reinforce joints and connections between two surfaces, typically at a 90-degree angle. These brackets are commonly made from steel, stainless steel, aluminium, or galvanised metal, providing high durability and resistance to corrosion.

Common types of angle brackets

- Heavy-duty angle brackets – built for high-load applications such as structural reinforcement and shelving support.

- 90-degree angle brackets – the most common type, used to join materials at a right angle for strong and stable connections.

- Perforated metal angle brackets – feature pre-drilled holes for easy fastening with screws, bolts, or nails.

- Adjustable angle brackets – designed for customisable angles to fit various applications.

Angle brackets are widely used in woodworking, construction, metal fabrication, and furniture assembly, ensuring secure and stable joints in both load-bearing and non-load-bearing applications.

How does an angle bracket work?

An angle bracket functions as a reinforcement component, distributing loads and preventing structural movement, separation, or collapse. These brackets are attached using screws, bolts, or nails, securing materials at a fixed angle.

How angle brackets provide strength

- Prevent separation – reinforces joints, stopping movement and shifting over time.

- Distribute load evenly – reduces stress on fasteners and connected materials, preventing bending or cracking.

- Increase stability – supports structures against lateral and vertical forces, improving durability.

- Allow for secure fixings – pre-drilled holes make installation quick, precise, and secure.

What are the benefits of angle brackets?

- High strength and stability - Heavy-duty angle brackets provide rigid structural reinforcement, preventing warping or movement in high-stress applications.

- Versatility for various applications - From framing and furniture assembly to shelf supports and metalwork, angle brackets offer endless applications across different industries.

- Corrosion and weather resistance - Galvanised and stainless steel angle brackets provide long-lasting performance, even in outdoor or high-moisture environments.

- Easy installation and secure fastening - Designed with pre-drilled holes, angle brackets allow for quick and accurate attachment with screws or bolts.

- Cost-effective structural reinforcement - Instead of using expensive custom welds or joinery techniques, angle brackets provide an affordable and reliable reinforcement solution.

When to use angle brackets?

Angle brackets are widely used in construction, woodworking, metal fabrication, and DIY projects. They are essential in situations where structural strength, load distribution, and secure connections are required.

Common uses of angle brackets

- Timber and metal framing – reinforcing wooden and metal joints in construction projects.

- Shelving and storage units – supporting heavy loads on shelves and racks.

- Furniture assembly – used in cabinets, tables, and chairs for added stability.

- Structural bracing – strengthening roof trusses, walls, and flooring structures.

- Fixing beams and posts – attaching wooden beams to concrete or steel posts for structural support.

- Outdoor and garden projects – providing stability for fencing, decking, and outdoor structures.

Angle brackets offer high reliability and load-bearing capability, making them an essential component in both small and large-scale construction projects.

How many angle brackets are needed?

The number of angle brackets required depends on the weight, size, and intended load of the structure.

General guidelines for bracket placement

- For light loads (shelving, small furniture) – 2 brackets per joint may be sufficient for smaller applications.

- For medium loads (structural framing, support beams) – 4 brackets per joint (two per side) help distribute weight more evenly.

- For heavy loads (roof supports, load-bearing applications) – multiple brackets per connection point may be required for maximum reinforcement.

- Factors to consider when determining the number of brackets

- Weight capacity – heavy-duty angle brackets can support higher loads with fewer brackets.

- Spacing and positioning – brackets should be evenly distributed to prevent stress on one area.

- Type of material – weaker materials such as softwood may require additional brackets for extra support.

Properly spacing and securing angle brackets ensures optimal strength and stability for any structure.

How to install angle brackets?

Installing angle brackets correctly is essential for maximising load-bearing capacity and structural stability.

Step-by-step guide to installing angle brackets

1. Choose the right bracket

- Select the correct size, thickness, and load capacity for your project.

- Use heavy-duty angle brackets for high-load applications.

2. Mark the position

- Align the bracket with the joint or connection point.

- Use a pencil or marker to outline the screw hole positions.

3. Drill pilot holes (if necessary)

- For wood or metal, pre-drill holes to prevent splitting or misalignment.

- Use a masonry drill bit if attaching brackets to brick or concrete surfaces.

4. Secure the bracket

- Attach the bracket using screws or bolts, ensuring a tight and flush fit.

- For heavy-duty applications, use anchor bolts or high-strength fasteners.

5. Check for alignment and stability

- Ensure the bracket is firmly secured and level.

- Apply additional reinforcement brackets if needed for extra support.

Properly installed angle brackets provide long-lasting structural reinforcement and prevent movement under load.

Angle brackets are essential components in construction, woodworking, and industrial applications, providing reinforcement, stability, and structural support. Whether using 90-degree angle brackets for joint reinforcement, heavy-duty angle brackets for load-bearing structures, or metal angle brackets for durability in harsh conditions, selecting the right bracket ensures stronger, safer, and more reliable connections.

By understanding how angle brackets work, their benefits, and correct installation methods, builders, engineers, and DIYers can achieve secure, long-lasting structures that withstand heavy loads and environmental stress.

Timber build advice:

-

How to soundproof a timber house?

Find out how -

How to connect timber to…..?

Find out how -

How to fix timber build noise issues?

Find out how

Need advice on your timber project?

Our team of experts are ready to assist you with any questions or guidance you may need for your timber construction. Whenever you're ready to delve deeper into the possibilities, feel free to reach out to us.